Hey folks, hard to believe it’s our 50th anniversary and that I’ve been here for almost 30 of those 50 years… wow, time sure does fly! In honour of Nautel’s 50th, I was tasked to come up with 50 Tips ‘n Tricks – no big chore there, I’ve never really run in to a shortage of things to talk about.

So, here goes… but wait, hold on… I still need something to talk about at our Annual NUG@NAB event in April – which I hear is going to be extra special this year to celebrate our 50th.

So, here’s a random sampling and if you’d like to hear 10 times more, then please come see me at the NUG@NAB on Sunday April 7th where I’ll present all 50 Tips n Tricks in detail. Register for our Annual NUG@NAB event here >

If you can’t make it to Las Vegas, the full list of 50 Tips ‘n Tricks will be published in a post-NAB issue of the Waves newsletter.

Random Sample

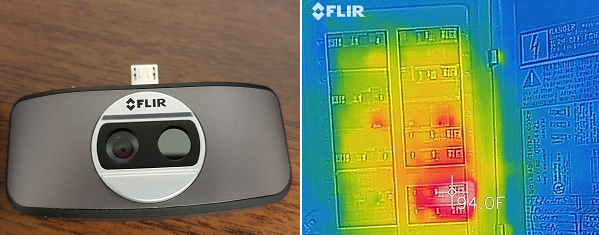

Tip #4 Check connections – every year or so, go through the facility and check connections, essentially any connection where a stranded wire goes into a compression type terminal (e.g. AC entrances to larger equipment). One tool that’s very useful in this regard is an infrared imager, such as this one by FLIR… it will show you any hot spots, before they become burned spots.

Tip #6 Use ferrites – I’m sure when I die, somebody will find a way to work ferrites into my eulogy! I’m a huge fan – while they won’t do anything all by themselves, in conjunction with a properly installed surge protector and good grounding practices, ferrites can mean the difference between surviving a storm and spending a lot of time and money recovering from one.

Photo credit – Kevin Trueblood, WGCU Public Media.

Tip #16 Bond grounds whenever possible – compression connections are the bane of grounding – copper is malleable and will compress over time, so unless a compression connection displaces 100% of the air in the connection, it will become loose over a few months or years.

Tip #16 Bond grounds whenever possible – compression connections are the bane of grounding – copper is malleable and will compress over time, so unless a compression connection displaces 100% of the air in the connection, it will become loose over a few months or years.

When possible, braze, silver solder or cadweld ground connections. When a compression connection simply must be used, put it on the site inspection checklist for regular tightening.

After 2-3 years, this could probably be dropped off the schedule, but it’s a good habit to keep going.

Tip #23 Make sure you can access your site – for real, or virtually. Obviously, site access is a challenge at times – in some sites, a very big challenge. In those situations, it’s a very good idea to have at least a virtual set of eyes available, to ensure everything is as it should be… like the door being closed.

Photo credit – Alex Hartman, Optimized Media Group.

Tip #42 If you have anything that involves something plugging into something else, oxidation of the connectors can be a concern. The cleaner we tend to use the most for this purpose these days is DeoxIT.

It comes in spray cans or tubes of liquid – I prefer the tubes for better control. Especially if you’ve got one of our older AMPFET 1 through 10 AM transmitters, you should have a tube of this (it’s the replacement to Cramolin Red). A drop on each pin of the Cinch-Jones plugs on those transmitters will get them humming along nicely.

It comes in spray cans or tubes of liquid – I prefer the tubes for better control. Especially if you’ve got one of our older AMPFET 1 through 10 AM transmitters, you should have a tube of this (it’s the replacement to Cramolin Red). A drop on each pin of the Cinch-Jones plugs on those transmitters will get them humming along nicely.

Where’s the rest?

Again, this was just a random sampling so if you’d like to hear 10 times more, then please come see me at the NUG@NAB on Sunday April 7th where I’ll present all 50 Tips n Tricks in detail. If you can’t make it to Las Vegas, the full list of 50 Tips ‘n Tricks will be published in a post-NAB issue of the Waves newsletter.

Until then, stay safe, and happy engineering!

Jeff

Jeff Welton, has worked with Nautel for 25+ years. He is currently the Nautel Sales Manager for U.S. Central Region but previously he spent 16.5 years as a Nautel Customer Service Technician.

Submissions for this Tips ‘n Tricks column are encouraged and if published you’ll receive a Nautel T-shirt. Submissions should be typed and emailed, with high resolution photos, to [email protected] using the subject line Tips ‘n Tricks.