Hey folks, it has been a while since I’ve done one of these and it was past due –it is good to be back, virtually speaking!

When I was asked about doing a Tips article for a Waves newsletter, my mind first went to the weather we’ve been having here in the eastern portion (and many other areas) of the Great White north… until a few nights ago, we had not had any measurable rainfall for a couple of months, my lawn is a lovely crispy brown and wells are going dry all over. So, I had leaned toward an article about the things we can do to help reduce fire risk at sites… clearing back brush, defoliation zones, building fire breaks, establishing sprinkler systems for sites with running water available, etc.

Then I thought about air handling – positive pressure to help reduce ingress of dust and soot, or closed air-conditioned systems (although those comes with their own maintenance challenges). We will talk more about that later, but while I was pondering this, I got a text from a friend in Alabama. Dan Gunter runs Alabama Broadcast Services in Opelika and is pretty good with a soldering iron. He had a few of the Tectrol power supplies from an older NV15 showing some red lights and figured he would give a shot at trying a repair.

Most folks know that we can arrange for repair of those supplies through U.S. Technologies – simply reach out to support@nautel.com to get an RMA and the details. Repairs are flat rate at just under 500.00 a shot, and U.S. Technologies is showing a 95% success rate. However, in some cases, time or budget dictate that you pursue other options, so when I come across info like this, I try to remember to share it. The first thing I always suggest is opening the supply up and looking for any blown track – that’s typically an indication that you’re not going to have a successful repair, either on your own or by sending it in, and it might be time to scrap and replace. In those situations, support can also set you up with a quote for a jig that will accommodate the newer UG132 supplies that we’re using in the GV and NVLT series transmitters. However, if it is not burned up and does not have obviously severe damage, there is often a good chance of making a repair work.

If asked, I would guess that the biggest killer of switching supplies is heat – even more so than lightning damage. Not having sufficient airflow or having a fan slowing down due to dust incursion (or even insects, in some cases I’ve seen), can cause them to overheat and either trip or, in the long term, cause electrolytics to fail faster. The general rule of thumb for most electronics is that for every degree that the ambient temperature goes up, the projected lifespan of the component goes down by a bit.

So, when Dan saw some dust buildup on the fans and boards on these supplies, he heated up the soldering iron and got to work – but I’ll let him tell the story.

Dan writes:

I have some good (and interesting) news to share with you regarding these Tectrol power supplies. Repaired them myself in a couple of hours, at a cost of less than $30. You might want to share this with other engineers.

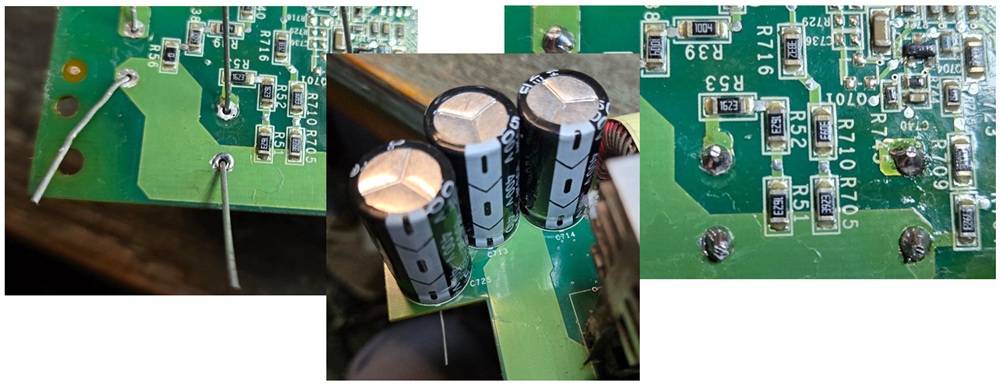

The fan was actually fine. I replaced all 7 of those 150 uF / 400V caps. On both power supplies, the one nearest the little connector for the fan was swollen. Common mode of failure in these? All I can say for now is that of the two I’ve chosen to have a go at repairing, replacing those caps fixed them.

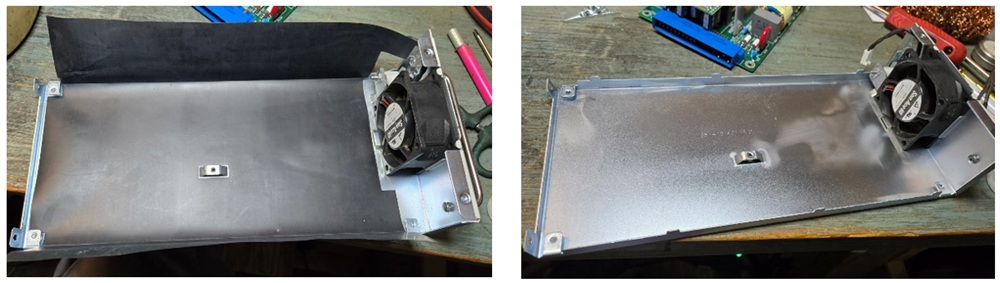

The inside of these things had gotten extremely nasty. That Boeing turbojet engine of a fan sucks everything into the power supply, including dirt, bugs, you name it. I wouldn’t have been surprised to have found a car or a human skeleton in there! When I got done cleaning everything thoroughly, they looked like they just left the factory. I even took that black dielectric sheet out and washed it with mild soap and water and dried it thoroughly. Much better now.

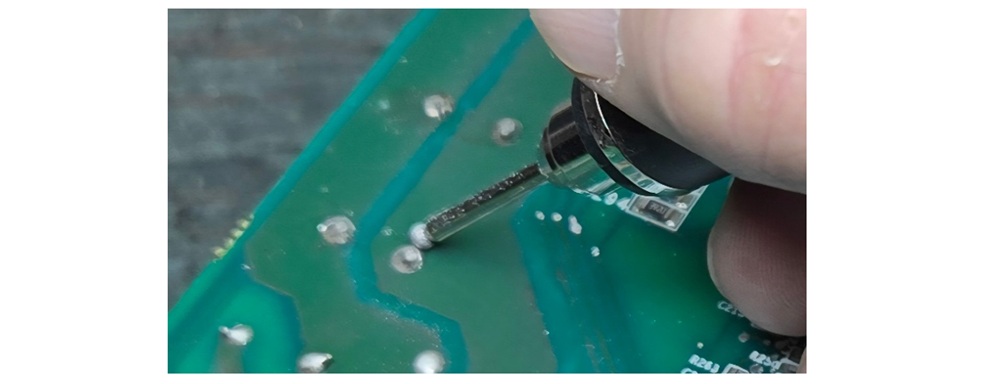

I used a small rotary tool and ball shaped grinding bit to remove a little conformal coating around solder joint before desoldering.

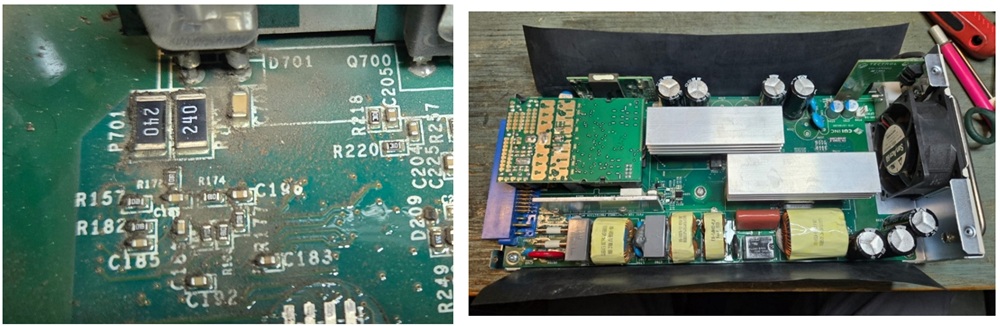

Another example of the nastiness on the board, which cleaned well with compressed air, a little isopropyl alcohol, and Kimwipes.

Three of the seven new caps going in, then soldered and flux cleaned off board.

You can see where the conformal coating got heated a bit in the process of desoldering and soldering, but no damage to board itself, traces, solder pads, or vias/thru-hole grommets. After a good cleanup, you wouldn’t think this was a fan which has been operating 24/7 for 13 years.

I almost forgot the final, critical step. No explanation should be required!

Thanks very much for the input, Dan! For those following along at home, the capacitors in question are 150uF, 400V aluminum electrolytics, with a 125 degree C temperature rating. Dan took a risk on Amazon, but you can also find them at Digikey, Mouser and most other electronics supply shops. For U.S. readers, I see them on Digikey at 3.55 ea, or 2.40 ea for a qty of 10… it’s worth a shot if you have a steady hand with a soldering iron! If you do give it a try, let me know if it was successful or not – in Dan’s words, “Could be really interesting to have a rough idea of what percentage of these power supplies end up just needing new caps and some TLC after years of surreptitiously doubling as shop-vacs in transmitter rooms.”

Back to the positive pressure comment in my opening paragraphs – airflow is always a challenge at a transmitter site. Even when there is plenty of well filtered airflow through the building, directing it so that it goes through the equipment can be an issue. Having positive pressure, both in the building as a whole, and in the equipment itself, can go a long way toward minimizing dust buildup that can clog up fans and reduce overall cooling of electronics. We’ve done a few discussions on this before – you can find webinars here (starting at the 30 minute mark) and here (the entire webinar).

The high points – if you know the total airflow requirement of all the equipment in your facility and have the ability to create a clean air room for intake, you can equip the clean air room with intake fans pulling in, say, 50% more than the total requirement, put coarse filters on the intake fans, then finer filters into the main transmitter room. Install exhaust fans to pull out 25% more than total amount of airflow needed for the equipment. If everything is laid out so that the path from intake to exhaust goes through the equipment, it will result in clean, well filtered air going through – and plenty of it – reducing dust and heat related failures significantly at a fraction of the cost of air conditioning. Obviously, this will not work in all environments… if you are in an area where the temperature routinely gets very hot, or very humid, then forced air cooling is not going to be an ideal solution. By the same token, salt air ingress from coastal sites may be an issue. However, properly done forced air can be a low-cost solution in many scenarios.

Those are my thoughts for the moment – thanks again to Dan Gunter at Alabama Broadcast Services for his input on this topic! See you all on my travels and happy engineering to all!

Jeff

Jeff Welton, has worked with Nautel for 30+ years. He is currently the Nautel Sales Manager for U.S. Central Region but previously he spent 16.5 years as a Nautel Customer Service Technician. A regular speaker and contributor on broadcast engineering, Jeff was elected to the Board of Directors for the Society of Broadcast Engineers in August 2023, and has been recognized with the following awards: 2020 NAB Radio Engineering Achievement Award; 2019 APRE Engineering Achievement Award; and 2018 SBE Educator of the Year Award.

Jeff Welton, has worked with Nautel for 30+ years. He is currently the Nautel Sales Manager for U.S. Central Region but previously he spent 16.5 years as a Nautel Customer Service Technician. A regular speaker and contributor on broadcast engineering, Jeff was elected to the Board of Directors for the Society of Broadcast Engineers in August 2023, and has been recognized with the following awards: 2020 NAB Radio Engineering Achievement Award; 2019 APRE Engineering Achievement Award; and 2018 SBE Educator of the Year Award.

Submissions for this Tips ‘n Tricks column are encouraged and if published you’ll receive a Nautel T-shirt. Submissions should be typed and emailed, with high resolution photos, to info@nautel.com using the subject line Tips ‘n Tricks.