Hey folks, hard to believe it’s our 50th anniversary and that I’ve been here for almost 30 of those 50 years… wow, time sure does fly!

In honour of Nautel’s 50th, I was tasked to come up with 50 Tips ‘n Tricks to present at our annual NUG@NAB Radio Technology Forum – no big chore there, I’ve never really run in to a shortage of things to talk about. Most of these topics come from previous Tips ‘n Tricks articles – go to all Tips ‘n Tricks articles.

So, here goes…

Tip 1 Keep it cool – everybody knows electronic things are happier when they’re cooler, and the difference is significant. Fans, for example, are typically specified at an ambient temperature of 40 degrees C (104 F). For every 10 degrees C (18 F) that temperature decreases, lifespan doubles. Thus, at 20 degrees C (68 F), a fan with a specified lifespan of 5 years (45,000 hrs, if I round up a bit), can be expected to run almost 20 years. This, of course, assumes no backpressure. Electrolytic capacitors also see significantly longer lifespans at lower ambient temperatures. This doesn’t mean you need to run out and install air conditioning – in many climates, simply having sufficient filtered air flowing through the room is enough, which leads to point #2…

Tip 2 Keep it clean – with respect to air filters, clogged filters reduce airflow. This increases operating temperatures for equipment, shortening lifespan. Inside the box, if the filters are letting dirt through, dust can cause arcing – which drastically affects on-air status in a lot of cases! Also, if a transmitter specifies a particular type of air filter, make sure not to change to something with higher density (less airflow), without checking with the manufacturer first… doing so can lead to higher device junction temperatures and increased failure rates.

Tip 2 Keep it clean – with respect to air filters, clogged filters reduce airflow. This increases operating temperatures for equipment, shortening lifespan. Inside the box, if the filters are letting dirt through, dust can cause arcing – which drastically affects on-air status in a lot of cases! Also, if a transmitter specifies a particular type of air filter, make sure not to change to something with higher density (less airflow), without checking with the manufacturer first… doing so can lead to higher device junction temperatures and increased failure rates.

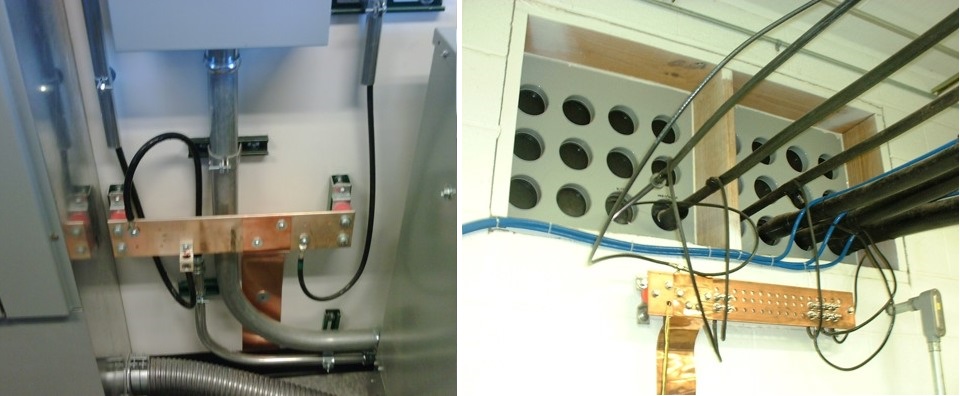

Tip 3 Keep it well grounded – this, more than anything, is probably the most important point in this list, from a site perspective. Single point grounding, with as few parallel return paths as possible, is key to long life for transmitters (and processors, remote controls, studio gear, etc.). Short, straight, low inductance ground runs will do a lot to help direct transient energy away from equipment. See our ‘Lightning Protection for Radio Transmitter Stations’ white paper.

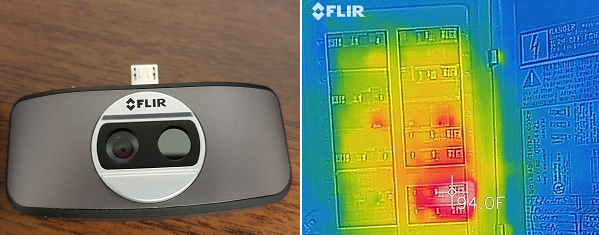

Tip 4 Check connections – every year or so, go through the facility and check connections, essentially any connection where a stranded wire goes into a compression type terminal (e.g. AC entrances to larger equipment). One tool that’s very useful in this regard is an infrared imager, such as this one by FLIR… it will show you any hot spots, before they become burned spots.

Tip 5 Critter proof – it’s no secret that rodents eat wires. Specifically, the insulation off wires. Grab some stainless-steel wool and a couple cans of spray foam and plug any holes you can find.

Tip 5 Critter proof – it’s no secret that rodents eat wires. Specifically, the insulation off wires. Grab some stainless-steel wool and a couple cans of spray foam and plug any holes you can find.

Remember that a field mouse can slip through a crack ½ cm (1/4”) wide!

Tip 6 Use ferrites – I’m sure when I die, somebody will find a way to work ferrites into my eulogy! I’m a huge fan – while they won’t do anything all by themselves, in conjunction with a properly installed surge protector and good grounding practices, ferrites can mean the difference between surviving a storm and spending a lot of time and money recovering from one.

Photo credit – Kevin Trueblood, WGCU Public Media.

Tip 7 Be safe – this should really be number one, and be repeated several times throughout! As we all get older and fewer folks have the radio bug required to put up with long hours, less than stellar working conditions and 24/7 on call, there aren’t as many engineers to go around. This means even longer hours and more tired engineers. Whenever possible, have somebody else at the site with you, even if they don’t know anything about electronics – show them where the circuit breaker is and make sure they know how to dial the local emergency number. CPR is a bonus. This is where finding that kid in tech courses at the local high school, or a community college, is worth its weight in gold… they get free mentoring and experience, you get somebody who could potentially keep you alive when things go wrong. More on safety later.

Tip 7 Be safe – this should really be number one, and be repeated several times throughout! As we all get older and fewer folks have the radio bug required to put up with long hours, less than stellar working conditions and 24/7 on call, there aren’t as many engineers to go around. This means even longer hours and more tired engineers. Whenever possible, have somebody else at the site with you, even if they don’t know anything about electronics – show them where the circuit breaker is and make sure they know how to dial the local emergency number. CPR is a bonus. This is where finding that kid in tech courses at the local high school, or a community college, is worth its weight in gold… they get free mentoring and experience, you get somebody who could potentially keep you alive when things go wrong. More on safety later.

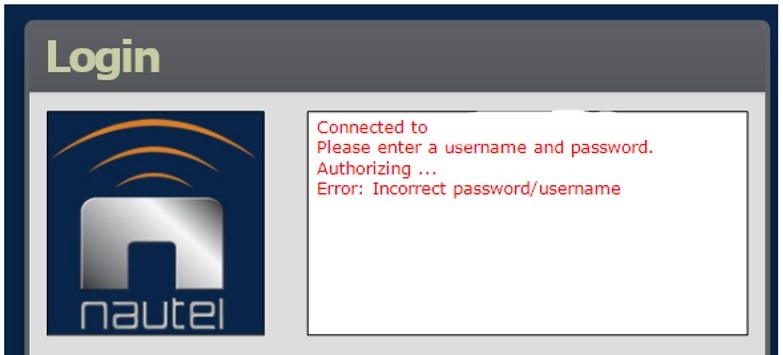

Tip 8 Change default passwords! I can’t believe, at this stage in the development of the internet and connected items, that this needs to be said – but with a simple search, I can still find several pieces of our gear and several hundred other items of broadcast technology tethered to the internet with default usernames and passwords active!!! If needed, write the password onto a piece of masking tape and stick it somewhere inside the equipment. It doesn’t matter what you need to do to remember it, or make sure the next guy can find it, but change it! “Password” is not a safe password. Neither is “admin” or “12345” …

Tip 9 Use a VPN – further to the above, stick an old computer at the site and load a cheap or free VPN client on it, then use it to connect to the transmitter. I’ve done more than one presentation on this, but in short, if nobody can see that your equipment exists, they’re going to be less likely to try to hack into it (but still change the default password)!

Tip 9 Use a VPN – further to the above, stick an old computer at the site and load a cheap or free VPN client on it, then use it to connect to the transmitter. I’ve done more than one presentation on this, but in short, if nobody can see that your equipment exists, they’re going to be less likely to try to hack into it (but still change the default password)!

You can find a list of free VPNs here.

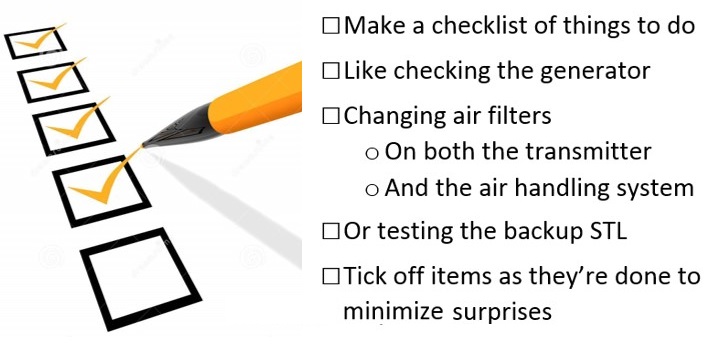

Tip 10 Do scheduled inspections – use the calendar function in your phone, email program, whatever. Build an inspection schedule that works for you and the situation at your site(s).

Tip 10 Do scheduled inspections – use the calendar function in your phone, email program, whatever. Build an inspection schedule that works for you and the situation at your site(s).

Check air filters, check hardware, lube/oil/scrub fuel for the generator – do these things on a strict schedule and they’re less likely to be overlooked.

Tip 11 Create scheduled checklists – being the belt and braces kind of person that I am, once the schedule for inspections is created, then make a checklist to pin to the wall beside your desk, or where ever. As things are done, check them off the list – it’s a fast way to remember if you’ve actually changed the filters or not, without running to the transmitter to check the date on them.

Bonus 11a… when you swap air filters, or batteries in a UPS or on a controller for a transmitter, remote control, etc., write the date on them, or on a piece of masking tape that’s stuck to them, so you always know the last time this item was changed.

Tip 12 Learn to “talk manager” – a lot of engineers complain about being treated as second class citizens and that may be so in some cases, but there are things that can help to counteract it. One of these is understanding that managers understand numbers… ROI, cost of operation, things like that. Putting engineering items in front of them phrased with those terms will go a lot further. As an example, “we bill x dollars per minute. Last year, we lost a total of y minutes of air time, due to z. A replacement/backup/alternate delivery method would cost us n.” If n is lower than y, you’ve got an argument that most managers will understand in a heartbeat! If n is five or six times higher than y, there really may not be a need after all.

An engineer should know what every station they look after bills or underwrites, down to the minute – otherwise, it’s hard to make a sound argument and what management hears is, “I want this, it’s shiny and expensive.” Learn to speak their language. Remember, you’re not saying that something will cost the station a certain amount of revenue, you’re asking them to invest that revenue to save much, much more! It’s all in the presentation.

Tip 13 Interface with others – there are so many forums available for tribal knowledge and so many experienced engineers willing to provide an education that is priceless. Some of the ones I follow now are (and if I miss any, I apologize):

On Facebook: The Broadcasting Club, I Take Pictures of Transmitter Sites, I Take Pictures of Radio Studios, Broadcast Engineers, Broadcast Engineering Notes, AM/FM/TV Broadcast Engineers, Radio Engineering and, of course, dozens of manufacturer specific pages.

Outside of Facebook: www.radiolists.net, www.broadcastengineering.info, www.crtech.groups.io for Christian Radio Broadcasters, www.pubtech.org for Public Broadcasting engineers, to name a few.

You’ll find a lot of manufacturers represented on these pages, as well as hundreds, if not thousands, of collective years of engineering experience.

Tip 14 Backup, backup, backup – any mission critical computer should be backed up regularly, in such a way that recovery is not a multi-hour challenge. A lot of devices have CF or SD cards in them… clean copies of these cards should be made and kept in a safe place.

Tip 14 Backup, backup, backup – any mission critical computer should be backed up regularly, in such a way that recovery is not a multi-hour challenge. A lot of devices have CF or SD cards in them… clean copies of these cards should be made and kept in a safe place.

Don’t forget, if you do a firmware or software update, it may be necessary to replace or update your backup, as well!

Tip 15 Surge protection – a good quality surge protector is a must for any broadcast facility, whether studio or transmitter site. It should be located as close to the mains as possible, grounded to the reference ground for the facility and ideally on its own breaker, so it can be taken out of service for maintenance, without disrupting operation. Of course, a series type surge protector does require taking the facility down when it’s being maintained, but it also provides additional levels of protection, so there’s a judgement call to be made, based on equipment value and the likelihood of a surge.

Tip 15 Surge protection – a good quality surge protector is a must for any broadcast facility, whether studio or transmitter site. It should be located as close to the mains as possible, grounded to the reference ground for the facility and ideally on its own breaker, so it can be taken out of service for maintenance, without disrupting operation. Of course, a series type surge protector does require taking the facility down when it’s being maintained, but it also provides additional levels of protection, so there’s a judgement call to be made, based on equipment value and the likelihood of a surge.

Tip 16 Bond grounds whenever possible – compression connections are the bane of grounding – copper is malleable and will compress over time, so unless a compression connection displaces 100% of the air in the connection, it will become loose over a few months or years.

Tip 16 Bond grounds whenever possible – compression connections are the bane of grounding – copper is malleable and will compress over time, so unless a compression connection displaces 100% of the air in the connection, it will become loose over a few months or years.

When possible, braze, silver solder or cadweld ground connections. When a compression connection simply must be used, put it on the site inspection checklist for regular tightening.

After 2-3 years, this could probably be dropped off the schedule, but it’s a good habit to keep going.

Tip 17 Strap is better than cable – 1000 feet of 2 AWG copper cable has a resistance of 0.1563 ohms. 1000 feet of 2” copper strap has a resistance of less than 0.06 ohms. This is before we calculate skin effect of high frequency ringing of a lightning surge, which is dependent on surface area… a 2” strap has 5 times the surface area of a 2AWG cable (four square inches per inch of length, vs. 0.810 square inches per inch of length for cable). Where possible, strap is by far a better choice for lightning protection and facility grounding.

Tip 17 Strap is better than cable – 1000 feet of 2 AWG copper cable has a resistance of 0.1563 ohms. 1000 feet of 2” copper strap has a resistance of less than 0.06 ohms. This is before we calculate skin effect of high frequency ringing of a lightning surge, which is dependent on surface area… a 2” strap has 5 times the surface area of a 2AWG cable (four square inches per inch of length, vs. 0.810 square inches per inch of length for cable). Where possible, strap is by far a better choice for lightning protection and facility grounding.

Tip 18 RTM!!! (or WTV ?) – translates to Read the Manual (or Watch the Video)… a lot of our most common calls are things that could be found by searching a PDF of the manual, or watching one of the many instructional videos you can find on our YouTube channel. For the VS series transmitters, where the manual is provided on a USB stick, the videos are also included with the transmitter.

Tip 19 Upconverters bad! When setting up a digital audio chain, it’s almost invariable that there will be at least one sample rate converter involved. If possible, up-conversions should be avoided – the bits can’t be put back, once they’ve been removed. Repeated sample rate conversions, especially up-conversions, will degrade audio, creating artifacts.

Tip 20 Standardize on an audio level – from microphone to transmitter, setting a standard audio level for the facility (whether it’s -10dBm, -4dBFS, or something completely different) will make troubleshooting throughout the audio chain much simpler. If a level is incorrect, it’s simply a matter of checking at various points in the chain to find out where it changed. Without a standard level, there’s no way of knowing what the level should be out of any piece of equipment.

Tip 20 Standardize on an audio level – from microphone to transmitter, setting a standard audio level for the facility (whether it’s -10dBm, -4dBFS, or something completely different) will make troubleshooting throughout the audio chain much simpler. If a level is incorrect, it’s simply a matter of checking at various points in the chain to find out where it changed. Without a standard level, there’s no way of knowing what the level should be out of any piece of equipment.

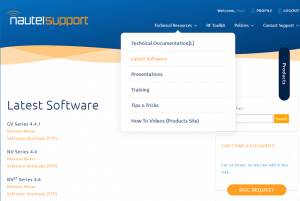

Tip 21 Software updates – I know, there’s a lot of feeling out there that, “if it isn’t broke, don’t fix it”. However, what we used to do with bags of parts and instructions to cut this, put that in, etc., we now do with a software update. At the very least, check release notes to verify that there is nothing in the update that could impact reliability of the equipment. Nautel software updates are available here.

Tip 21 Software updates – I know, there’s a lot of feeling out there that, “if it isn’t broke, don’t fix it”. However, what we used to do with bags of parts and instructions to cut this, put that in, etc., we now do with a software update. At the very least, check release notes to verify that there is nothing in the update that could impact reliability of the equipment. Nautel software updates are available here.

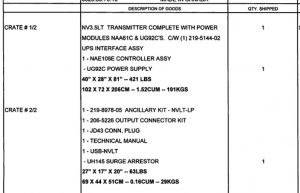

Tip 22 Packing lists – check them. While we do forget stuff on occasion (we’re only human!), there are multiple sets of eyes looking at every piece that we ship. A lot of times I’ll get a call that we forgot something that was never ordered. Or that we didn’t include something because it was in the other crate that hasn’t been opened yet. The packing lists will tell you what to expect, what crate to look for it in and – if we did happen to forget something, will verify for you that it is supposed to be there.

Tip 22 Packing lists – check them. While we do forget stuff on occasion (we’re only human!), there are multiple sets of eyes looking at every piece that we ship. A lot of times I’ll get a call that we forgot something that was never ordered. Or that we didn’t include something because it was in the other crate that hasn’t been opened yet. The packing lists will tell you what to expect, what crate to look for it in and – if we did happen to forget something, will verify for you that it is supposed to be there.

Tip 23 Make sure you can access your site – for real, or virtually. Obviously, site access is a challenge at times – in some sites, a very big challenge. In those situations, it’s a very good idea to have at least a virtual set of eyes available, to ensure everything is as it should be… like the door being closed.

Photo credit – Alex Hartman, Optimized Media Group.

Tip 24 Remote access – it’s also a good idea to have backup access. If you have a single IP link to the transmitter site, how do you control the transmitter if it goes down? In a lot of cases, you can put together a Wi-Fi bridge as a temporary (or even permanent) STL for less than 2000.00. Alternately, there are companies who can provide low cost 3G data capability, such as these folks.

Tip 24 Remote access – it’s also a good idea to have backup access. If you have a single IP link to the transmitter site, how do you control the transmitter if it goes down? In a lot of cases, you can put together a Wi-Fi bridge as a temporary (or even permanent) STL for less than 2000.00. Alternately, there are companies who can provide low cost 3G data capability, such as these folks.

Tip 25 AUI companion – it’s been a long time coming, but we’re starting to roll out the AUI companion… it’s on limited release at the moment and going through final tests but should be there soon. This is where you’ll be able to turn things on and off with your phone (use caution with turning things off… somebody may get upset!) I know, it’s not really a tip exactly, but I’m excited about this.

Tip 25 AUI companion – it’s been a long time coming, but we’re starting to roll out the AUI companion… it’s on limited release at the moment and going through final tests but should be there soon. This is where you’ll be able to turn things on and off with your phone (use caution with turning things off… somebody may get upset!) I know, it’s not really a tip exactly, but I’m excited about this.

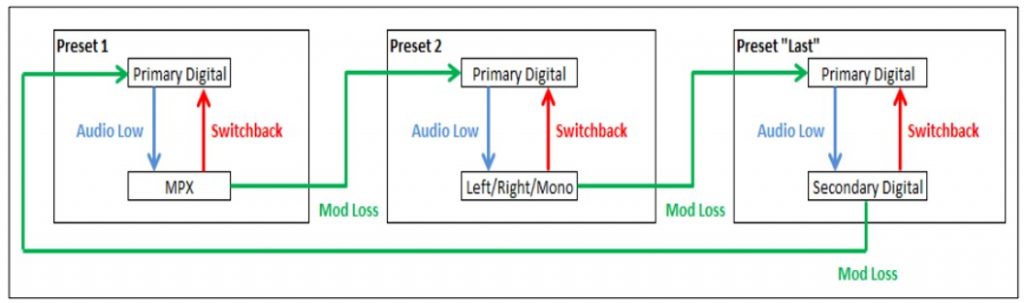

Tip 26 Using audio backups – if you’re configured with one of our systems to use backup audio paths, you can set up multiple paths with will all revert to the main feed when it returns. Chuck Kelly and I covered this topic in this GV Series Webinar. The part about multiple backup audio paths can be found at the 28:47 mark.

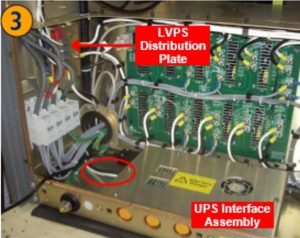

Tip 27 UPS Interface – a lot of folks ask about this, as I’ll always offer it as a standard part of any system I configure. Effectively, because the controller has software, it takes some time for it to restart after a short interruption in AC power, about six seconds. During a storm, where the lights may flicker half a dozen times, this can be annoying, to say the least!

Tip 27 UPS Interface – a lot of folks ask about this, as I’ll always offer it as a standard part of any system I configure. Effectively, because the controller has software, it takes some time for it to restart after a short interruption in AC power, about six seconds. During a storm, where the lights may flicker half a dozen times, this can be annoying, to say the least!

The UPS Interface allows our customers to plug their double conversion UPS into the transmitter and keep the controller energized during short power outages, so the return to on-air status is only fractions of a second after the lights come back on. Fear not, if you’ve got an NV, NVLT or GV transmitter that doesn’t have the UPS interface installed, it can be done as a field upgrade. Current revisions also include a third low voltage power supply, which runs in parallel with the existing LVPS(s), so that when (not if) the UPS fails, you’re still on the air… at least until the lights go out again!

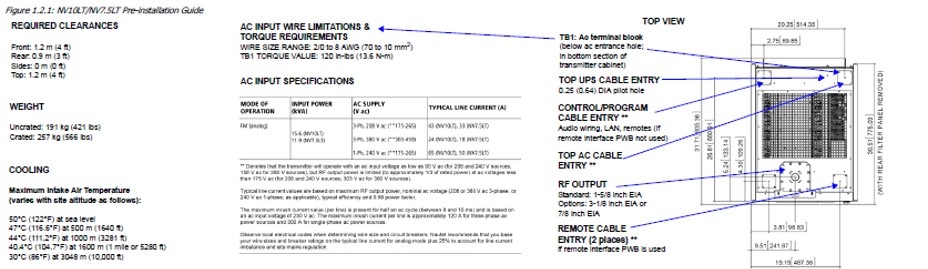

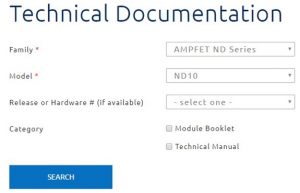

Tip 28 Where to find stuff? Another question/comment that I get a lot is that it’s hard to find things in our manuals. That can be true, there is a lot of information and it’s broken into task-oriented sections. For example, anything on current draw or air handling/cooling, which are questions you’d normally tackle before putting a transmitter in place, can be found in the pre-installation manual.

The four manual sections are:

The four manual sections are:

- Pre-Installation – what to know before you put the transmitter in

- Installation – things to know during the unloading and installing process

- Operations & Maintenance – stuff you’ll encounter day-to-day after it’s on air, such as all of the AUI information and how to configure things

- Troubleshooting – replacing modules, troubleshooting alarms and the like

Knowing which book to go to can be half the battle sometimes! Nautel documentation is stored here on our Support website; NUG login required to access.

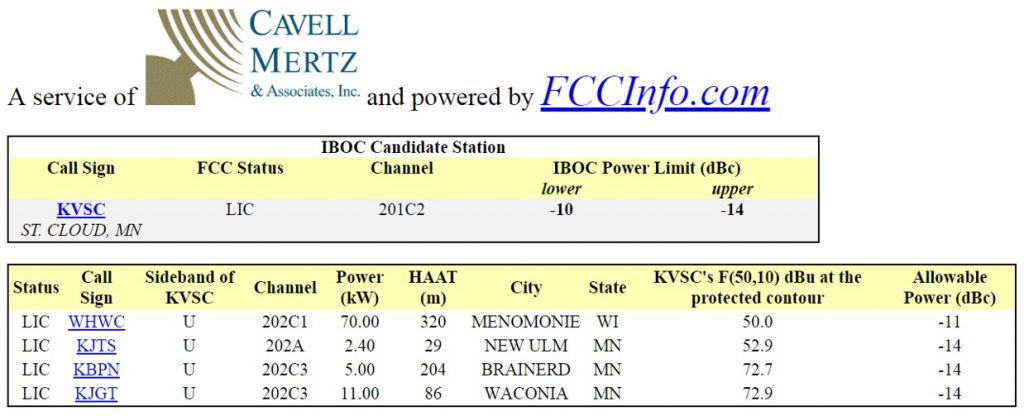

Tip 29 HD Radio also creates a lot of calls – the big thing to remember here is that, for FM, the digital carriers are amplitude modulated on top of the FM analog carrier. This means that care needs to be taken with respect to both peak power and voltage ratings for coax, antennas and fittings, but also with regards to the necessary transmitter size. The amount of the impact is directly related to the HD injection desired. In short, -20dBc (digital power = 1% of analog power) is the legal minimum, this will drive a translator but won’t provide any reasonable digital coverage at all, not even to the city grade contour. -14dBc injection (4% of analog power) will give solid city grade coverage and may get out to the 54dBu contour in some situations. -10dBc will do a fair job of replicating, and in some cases exceeding, the analog coverage.

Nautel’s FREE RF Toolkit includes a useful HD Radio Calculator – calculate a proposed IBOC power increase using our exclusive Asymmetrical IBOC Sideband Elevated Power Calculator; NUG login required to access. There are a lot of other considerations and I’ve done a few presentations on them, I’m happy to share as needed!

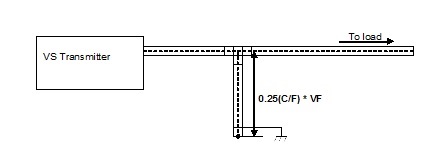

Tip 30 One other thing I get asked a lot is what size breaker a specific system will need. It’s easy math – take your TPO (transmitter power), divided by the AC voltage (I use 185V, as that’s the brownout point where the transmitter reduces power, above that it will make full power). That will give total current for an FM transmitter – if you have a three phase supply, divide again by the square root of three (1.732) … that will give you the current per phase. If you have an AM transmitter, multiply this number by 1.4 to allow for modulation peaks and heavy compression. Now you have your maximum nominal line current – multiply that by 1.25 to add 25% headroom and size to the next standard breaker size above that, then you’ll be good to go.

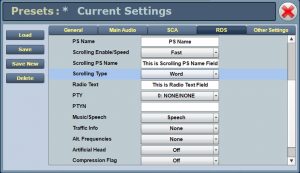

Tip 31 RDS tips – I think maybe the biggest issue we see with RDS these days, once it’s configured and running, is with the VS transmitters… the ARM processor can get overwhelmed if it’s being hit with too much data. One thing that seems to help nicely is to slow down the rate at which the automation system sends the RDS data to the transmitter. On my station, we send the RDS data once per cart change – whenever a new spot is fired, the data goes and that’s it until the next song/spot/liner/etc. It works well. Some automation systems have a default setting that’s much more frequent – I encountered one that was set to send the RDS data every half a second. They were getting all kinds of lockups and hiccups on the radio displays. Backing this down to the maximum this system would allow, once every 20 seconds, seems to have done a good job of pretty much resolving the issue. Beyond that, it’s important to remember that the automation system needs to be sending the data to the right port (7005), so it needs to address xxx.xxx.xxx.xxx:7005, not just the IP address.

Tip 31 RDS tips – I think maybe the biggest issue we see with RDS these days, once it’s configured and running, is with the VS transmitters… the ARM processor can get overwhelmed if it’s being hit with too much data. One thing that seems to help nicely is to slow down the rate at which the automation system sends the RDS data to the transmitter. On my station, we send the RDS data once per cart change – whenever a new spot is fired, the data goes and that’s it until the next song/spot/liner/etc. It works well. Some automation systems have a default setting that’s much more frequent – I encountered one that was set to send the RDS data every half a second. They were getting all kinds of lockups and hiccups on the radio displays. Backing this down to the maximum this system would allow, once every 20 seconds, seems to have done a good job of pretty much resolving the issue. Beyond that, it’s important to remember that the automation system needs to be sending the data to the right port (7005), so it needs to address xxx.xxx.xxx.xxx:7005, not just the IP address.

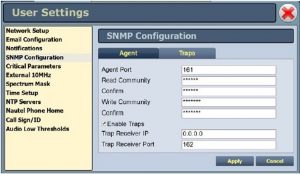

Tip 32 SNMP has similar requirements – the ports for the SNMP client and agent need to be opened through your firewall (assuming there is a firewall!). Thus, ports 161 and 162 need to be accessible. Beyond that, having a good SNMP manager makes control quite simple and with less bandwidth than the graphic based AUI. I’ll confess I’m still learning what’s out there for SNMP, so feel free to send me your manager of choice suggestions!

Tip 32 SNMP has similar requirements – the ports for the SNMP client and agent need to be opened through your firewall (assuming there is a firewall!). Thus, ports 161 and 162 need to be accessible. Beyond that, having a good SNMP manager makes control quite simple and with less bandwidth than the graphic based AUI. I’ll confess I’m still learning what’s out there for SNMP, so feel free to send me your manager of choice suggestions!

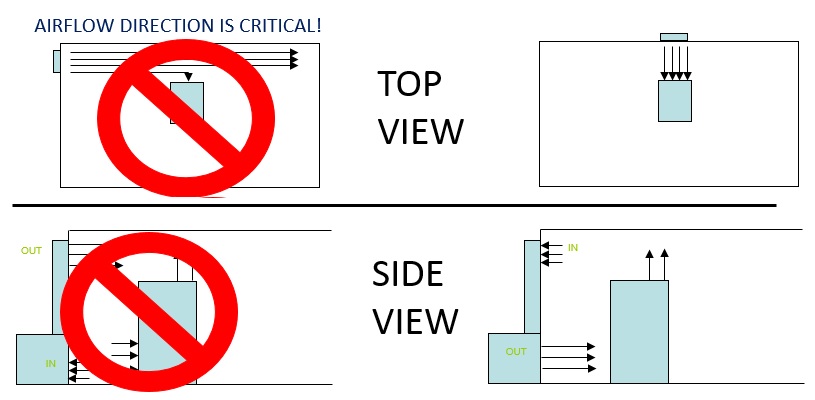

Tip 33 Airflow is another thing I see done less than optimally on a regular basis. In an ideal situation, the building would be positively pressurized (more air drawn in than exhausted out), with the incoming air all well filtered. After that, bring in a lot more air than the total transmitter throughput requirement and exhaust a bit more than the throughput requirement and you’re good. For example, if the transmitter needs 1000 CFM of airflow, bring in 2000 CFM and exhaust 1500 – that will keep dust from entering through every crack and crevice in the building, keep the fans in the transmitter at static pressure, extending life, and keep the transmitter near ambient temperature. If you’re ducting the transmitter, leave a gap of 10 cm or so (4-5 inches) between the exhaust hood and the roof of the transmitter. That way, when (not if) the room exhaust fan fails, the transmitter can dump air into the room until you can get the fan repaired.

Tip 33 Airflow is another thing I see done less than optimally on a regular basis. In an ideal situation, the building would be positively pressurized (more air drawn in than exhausted out), with the incoming air all well filtered. After that, bring in a lot more air than the total transmitter throughput requirement and exhaust a bit more than the throughput requirement and you’re good. For example, if the transmitter needs 1000 CFM of airflow, bring in 2000 CFM and exhaust 1500 – that will keep dust from entering through every crack and crevice in the building, keep the fans in the transmitter at static pressure, extending life, and keep the transmitter near ambient temperature. If you’re ducting the transmitter, leave a gap of 10 cm or so (4-5 inches) between the exhaust hood and the roof of the transmitter. That way, when (not if) the room exhaust fan fails, the transmitter can dump air into the room until you can get the fan repaired.

Tip 34 Since a lot of sites do not have ideal air flow, or filtering, occasionally it’s necessary to take a transmitter down and clean the crud out of it.

A lot of folks prefer compressed air for this, but I have to say I’d much rather have a vacuum. My theory is that compressed air relocates the dirt from some place where it wasn’t causing any issues to some place where it might, where a vacuum removes it from the transmitter totally. One caveat here, though – plastic ShopVac hoses can build up a lot of static. It’s a good idea to take a three or four foot piece of 14AWG stranded wire, strip about six inches of insulation from one end, wrap it near the suction end of the vacuum hose and tape it in place, then connect the other end to the transmitter chassis. This will keep the hose from building up static and potentially frying some CMOS devices while you work

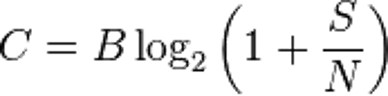

C= Channel capacity, B= Channel BW, S= signal power (average over BW), N= noise (average over BW)

Tip 36 We’re obviously aware that Flash is on the way out, with a hard end to support in 2020. Recently, Google Chrome did an update that ended permanent “allow” exceptions for pages that contained Flash content. Aaron Read, with WIPR in Providence, was kind enough to send me a workaround to allow this. Here it is below, in Aaron’s words (please note, this may not work with all versions of Chrome, but was good when Aaron found it!)

“In the URL bar, type (minus the quotes)

“chrome://flags/#enable-ephemeral-flash-permission”

The first item in the list that appears should be “Enable Ephemeral Flash Permissions”.

In the pull-down menu to the right, select DISABLED and relaunch Chrome.

Your ability to store “allow flash on these sites”

(under chrome://settings/content – search on “flash”) should be restored now.

And it should remember any stored exceptions from before, too.”

Tip 37 Streaming audio is always good for a call or two – one of the things that’s important to remember is that we only support MP3 and WAV formats at this point. That may change at some point, but at least for now, it’s what you’ve got. The audio needs to be 16-bit stereo, at a sample rate of 48kHz or lower. We’ve tested bit rates up to 384kHz, but haven’t tested any higher than that, so no guarantees. Also, if using Shoutcast, the source must be a server (a Barix Shoutcast configuration is NOT a server) and it must be in public mode.

Figure 2 – if it can be seen, it can be hacked

Beyond that, realize that WiFi can easily be detected and a “man in the middle” scenario set up, so make sure that any WiFi access is well encrypted and secured.

![]() Tip 39 One of your best resources for info on Nautel transmitters can be found on our website. On the Support tab, you’ll see several links identified as “sign in with NUG” – NUG being Nautel Users Group.

Tip 39 One of your best resources for info on Nautel transmitters can be found on our website. On the Support tab, you’ll see several links identified as “sign in with NUG” – NUG being Nautel Users Group.

This will give you access to the FREE RF Toolkit, where you can find the path calculator mentioned earlier and a coverage plotter, along with an HD Radio coverage tool, that will let you know how much injection any station in the U.S. can use. There are occasional additions and tweaks to this section, so it’s worth checking in on occasion – NUG membership also gives you access to PDF copies of manuals for all current and a lot of our legacy equipment, it can be a lifesaver if you arrive at the site and discover the manuals aren’t there!

Tip 40 On the topic of “speaking manager” again, one thing that’s mentioned on occasion is that some GMs will push against engineers, either staff or contract, making transmitter site visits for maintenance purposes, or against getting groundskeepers to keep the shrubbery cut back. Sometimes it’s helpful to use a car analogy – just as a car may be running 15,000 miles after the oil change was due, it certainly won’t run forever without an oil change.

Tip 40 On the topic of “speaking manager” again, one thing that’s mentioned on occasion is that some GMs will push against engineers, either staff or contract, making transmitter site visits for maintenance purposes, or against getting groundskeepers to keep the shrubbery cut back. Sometimes it’s helpful to use a car analogy – just as a car may be running 15,000 miles after the oil change was due, it certainly won’t run forever without an oil change.

Periodic site visits to change filters, grab meter readings, make sure everything is working the way it should be are the transmitter equivalent to an oil change and tune-up… over the long run, it saves a lot more money than it costs. Keeping the brush cut back reduces the risk of fire and, in some areas, snake bite. It’s a minimal investment in keeping the engine of the cash machine running, so to speak. For more information on basic housekeeping read this previous Tips article Transmitter Site Maintenance and Housekeeping.

Tip 41 In a few situations, we’ve had customers with issues with PAs failing, always in 15kW and higher FM transmitters and, so far at least, always with one specific brand of antenna. If you call in with a situation involving repeated failures of PA1 or sometimes 2 in power module 7, don’t be surprised if the tech tells you, “oh, you must have a brand x antenna”. In some antennas, there is a shorting stub installed as part of the antenna. It’s purpose is to provide a path for lightning energy that prevents antenna components from failing and it works well. Unfortunately, that also means that energy is now heading down the coax.

The nature of hybrid combining in a transmitter is that there are several layers of phase shift involved in the various combiners. It means that at least one PA is, electrically speaking, going to be located at the transmitter output connector. In a situation like this, the best solution is to install a quarter wave stub at the transmitter output, to provide a high current DC path to ground before that energy sees the PAs. Even in the best grounded site, this can be an issue, so just keep it in mind. For any transmitter, a shorting stub at the output is useful as another layer of lightning protection – I did an article on building your own quarter wave stub awhile back. You can find it at the end of this edition of Tips N Tricks.

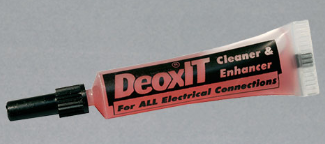

Tip 42 If you have anything that involves something plugging into something else, oxidation of the connectors can be a concern. The cleaner we tend to use the most for this purpose these days is DeoxIT.

It comes in spray cans or tubes of liquid – I prefer the tubes for better control. Especially if you’ve got one of our older AMPFET 1 through 10 AM transmitters, you should have a tube of this (it’s the replacement to Cramolin Red). A drop on each pin of the Cinch-Jones plugs on those transmitters will get them humming along nicely.

It comes in spray cans or tubes of liquid – I prefer the tubes for better control. Especially if you’ve got one of our older AMPFET 1 through 10 AM transmitters, you should have a tube of this (it’s the replacement to Cramolin Red). A drop on each pin of the Cinch-Jones plugs on those transmitters will get them humming along nicely.

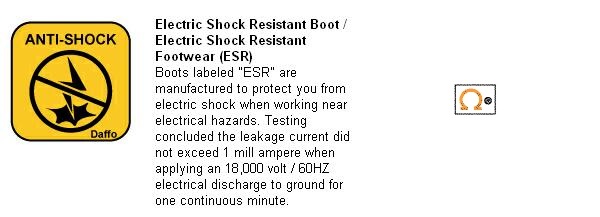

Tip 43 Another safety topic I beat the drum on is making sure everybody has some basic PPE. At the minimum, anybody working on transmitters should have EH rated footwear (ESR in Canada). Shock resistant shoes can keep you alive at the end of a long day when you forget to check and see if the discharge resistors are still intact.

Beyond that, if working in an ATU, or in a tube transmitter, a grounding stick isn’t a nice thing to have, it’s a necessity. If you don’t have one, you can make one quite quickly with a wooden broomstick, a roll of duct tape and a set of booster cables from your truck. If you’re working on a transmitter that does have a grounding stick, double check to see if it has a discharge resistor between the ground wand and actual ground… if it does, verify that the resistor is still functional. Then measure to be sure! When working with RF or high voltage, the carpenter’s adage could be adapted… measure twice to touch once. Read more on Transmitter Site Safety.

Tip 44 It’s not just the heat, it’s the humidity! On the topic of airflow mentioned in #33, humidity may be the deciding factor between forced air and air conditioning. If the humidity is too high, it will condense on any hard surface – transmitters do NOT like to be wet! While there are industrial dehumidifiers, I’ve yet to encounter one that will handle several hundred CFM of air exchange, so forced air may not be an option in an area where humidity is routinely above 80-90%.

Tip 44 It’s not just the heat, it’s the humidity! On the topic of airflow mentioned in #33, humidity may be the deciding factor between forced air and air conditioning. If the humidity is too high, it will condense on any hard surface – transmitters do NOT like to be wet! While there are industrial dehumidifiers, I’ve yet to encounter one that will handle several hundred CFM of air exchange, so forced air may not be an option in an area where humidity is routinely above 80-90%.

Tip 45 One of the best resources (I may be biased) is our Nautel Users Group (NUG). We have an annual session at NAB on the Sunday prior to the show floor opening. It typically covers any new developments, input and ideas from industry experts and a few of these tips and tricks! If you’re going to be in Las Vegas for NAB it’s definitely worth coming in on Saturday and spending Sunday morning with us – we’ll even buy lunch!

Tip 45 One of the best resources (I may be biased) is our Nautel Users Group (NUG). We have an annual session at NAB on the Sunday prior to the show floor opening. It typically covers any new developments, input and ideas from industry experts and a few of these tips and tricks! If you’re going to be in Las Vegas for NAB it’s definitely worth coming in on Saturday and spending Sunday morning with us – we’ll even buy lunch!

Tip 46 I HATE WIRING UP D-SUB CONNECTORS! The older I get, the harder it is to solder up a 25 pin D-sub connector. Fortunately, there’s a few companies that make handy little D-sub to Phoenix terminal breakout assemblies. The one I use most at the moment is Winford Engineering – for remote interface of our gear, you’d need one each 25-pin male and female and a 9-pin male assembly.

Tip 46 I HATE WIRING UP D-SUB CONNECTORS! The older I get, the harder it is to solder up a 25 pin D-sub connector. Fortunately, there’s a few companies that make handy little D-sub to Phoenix terminal breakout assemblies. The one I use most at the moment is Winford Engineering – for remote interface of our gear, you’d need one each 25-pin male and female and a 9-pin male assembly.

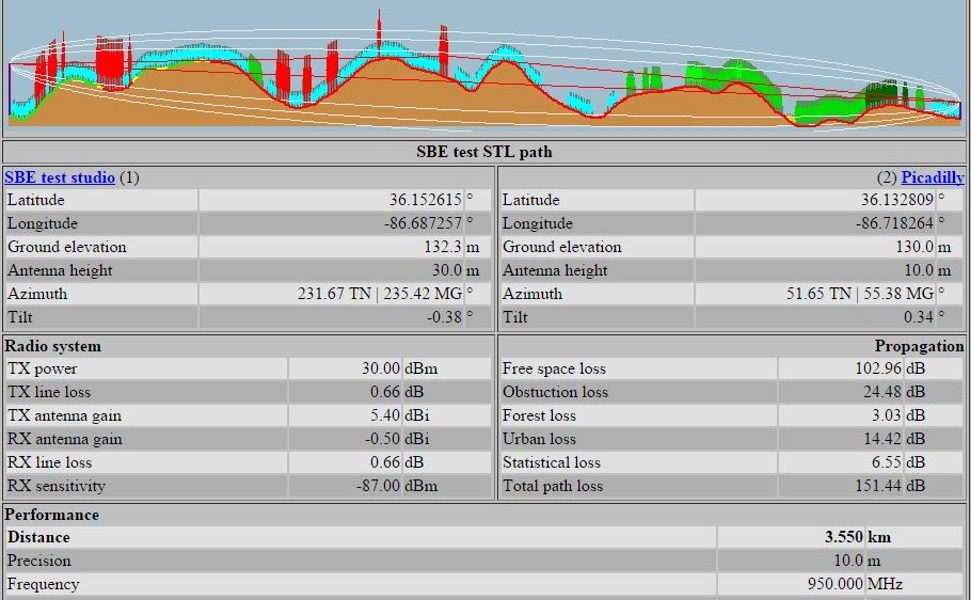

Tip 47 FREE RF Toolkit – I ran into a situation on a local station that I help with whenever I can, where we were looking at using a wireless IP bridge for an STL. The provider had a path tool on their website and the path had been run successfully. Shortly after I came on board, I ran the same path on another calculator and discovered it wouldn’t work… it turns out that the software used by the bridge provider did not account for foliage – we’ve got old growth forest with 60-foot trees on the ridge we needed to clear. The IP bridge was a no-go. If you go to our FREE RF Toolkit you can do path plots – and you do have the option to turn foliage off or on (default is on). It’s a useful tool and there is a webinar on how to use it, as well!

Tip 48 One other air handling note. When planning a new installation, pay careful attention to airflow direction through the equipment. For example, our higher power FM transmitters bring most of the air in from the rear, but there is also air coming in the front to cool the power supplies. This was done on purpose, to reduce the number of times the air is redirected internally, reducing back pressure so the fans don’t have to work as hard, reducing temperature increase through the equipment and generally keeping everything happier. However, it does mean that there needs to be some positive pressure in front of the transmitter as well as behind it, or those benefits are negated. This would hold true for any transmitter – always take a moment to look at the direction of airflow and ensure that any cooling or ventilation system is configured to accommodate it.

Tip 49 Site security tip – a few things on site security… floodlights are inexpensive and provide good visibility if anything is awry before you get out of your vehicle. You can get high intensity LED floodlights these days that won’t hurt the power bill either!

Tip 49 Site security tip – a few things on site security… floodlights are inexpensive and provide good visibility if anything is awry before you get out of your vehicle. You can get high intensity LED floodlights these days that won’t hurt the power bill either!

Beyond that, if you have IP access to the site, IP cameras, especially the indoor ones, are really getting better in quality and lower in price. The Wyze cam shown earlier in this article comes in around 40.00 from Amazon – I have a few in my house and they work well, with motion detector alerting, recording capability and just the ability to access the cam online and see that everything looks okay before you’re even in eyesight of the transmitter site. With copper theft and various other miscreants, remote transmitter sites aren’t as safe a place to be as they used to be, so some security is a good idea.

Tip 50 One of the things I touch on in my lightning protection presentations, while I’m waxing eloquent on the virtues of ferrites, is using a ferrite as an AM troubleshooting tool. If you put a ferrite toroid on the coax coming out of an AM transmitter, it should sit there at ambient temperature. If it gets warm, it means the feed current down the center conductor is not the same as the return current on the shield – either you have a ground loop, or a bad shield connection somewhere between the transmitter and the antenna. In a directional situation, you can put additional ferrites between the phasor and the individual ATUs to quickly identify the source of any current imbalances. In a pinch, you can also grab a couple of resistors and a handful of wire and turn a toroid into a handy dandy current probe…by carefully counting the turns of wire through the toroid to match the resistance you’re terminating the two ends with, you will know the exact ratio of current to voltage and can get a pretty accurate measurement of RF current through a wire. I included an article in Tips N Tricks on building your own current probe that was originally written by one of our Navaid folks several years ago – you can find it here.

Tip 50 One of the things I touch on in my lightning protection presentations, while I’m waxing eloquent on the virtues of ferrites, is using a ferrite as an AM troubleshooting tool. If you put a ferrite toroid on the coax coming out of an AM transmitter, it should sit there at ambient temperature. If it gets warm, it means the feed current down the center conductor is not the same as the return current on the shield – either you have a ground loop, or a bad shield connection somewhere between the transmitter and the antenna. In a directional situation, you can put additional ferrites between the phasor and the individual ATUs to quickly identify the source of any current imbalances. In a pinch, you can also grab a couple of resistors and a handful of wire and turn a toroid into a handy dandy current probe…by carefully counting the turns of wire through the toroid to match the resistance you’re terminating the two ends with, you will know the exact ratio of current to voltage and can get a pretty accurate measurement of RF current through a wire. I included an article in Tips N Tricks on building your own current probe that was originally written by one of our Navaid folks several years ago – you can find it here.

Okay, that’s 50 tips for 50 years… and my fingers are exhausted! Thanks for hanging in there and thanks very much to all of our customers and industry friends for 50 years of support and growth. Here’s looking forward to another 50 (although I’ll confess I doubt I’ll be here to write the 100th anniversary Tips article!). Until next time, play safe and happy engineering.

If you’re interested in seeing this or any of the other presentations from the NUG@NAB Radio Technology Forum you can view them here.

Jeff

Jeff Welton, has worked with Nautel for 25+ years. He is currently the Nautel Sales Manager for U.S. Central Region but previously he spent 16.5 years as a Nautel Customer Service Technician.

Submissions for this Tips ‘n Tricks column are encouraged and if published you’ll receive a Nautel T-shirt. Submissions should be typed and emailed, with high resolution photos, to [email protected] using the subject line Tips ‘n Tricks.